By Peter, Master Electrician & Certified HVAC Professional

BOTTOM LINE UP FRONT (BLUF)

I am a Master Electrician and Certified HVAC Professional who lives and works right here in Fairfax, Loudoun, Arlington, and Prince William Counties. For over 20 years, I’ve seen countless Northern Virginia homeowners struggle because they hire one guy for their cooling and another for their power, only to have them blame each other when something goes wrong. This guide is my promise to you: I will give you the inside track on how your electrical and HVAC systems must work together seamlessly to ensure your home is safe, efficient, and comfortable through NoVA’s extreme weather swings. Whether you need a new heat pump, a critical panel upgrade, or a simple repair, I’ll show you why trusting a dual-trade professional is not just convenient; it is the single smartest and safest investment you can make in your home.

If you are asking these questions, you are in the right place; this article is for you.

-

Do I need to upgrade my electrical panel before installing a heat pump, EV charger, or other high-demand system?

-

Why do my HVAC problems sometimes turn out to be electrical issues (or vice versa)?

-

What should I know about keeping my home safe and efficient during NoVA’s extreme heat, cold, and power surges?

-

How can a combined electrical plus HVAC professional save me time, money, and unnecessary service calls?

-

What are the real costs and potential rebates for electrical upgrades and high-efficiency HVAC systems like heat pumps?

Table of Contents

- Chapter 1: The Dual Advantage: Why NoVA Needs PRO Electric plus HVAC

(The Personal Introduction and the Core Thesis) - Chapter 2: Achieving Climate Mastery: Core HVAC Systems & NoVA’s Demands

(Deep Dive into ACs, Furnaces, and Boilers) - Chapter 3: Powering the Modern Home: Essential Electrical Safety and Capacity

(Panel Upgrades, Wiring Integrity, and Code Compliance) - Chapter 4: The Strategic Edge: Heat Pumps, Mini-Splits, and Local Rebates

(Focus on Efficiency, Zoning, and Incentives for NoVA Homeowners) - Chapter 5: Fortress Home: Generators, Power Outages, and Surge Protection

(Preparing for Blizzards, Derechoes, and the Inevitable Power Loss) - Chapter 6: When Things Go Wrong: My Technician’s Guide to Troubleshooting and Emergency Calls

(Specific Diagnostic Steps and Real-World NoVA Anecdotes) - Chapter 7: The Unsung Hero: Detailed Preventative Maintenance and System Lifeline

(Why the Annual Checkup Saves Thousands in the Long Run) - Chapter 8: The Electrified Home: EV Charging and High-Efficiency Upgrades

(Preparing Your Home’s Electrical System for the Future of Transportation and Appliances) - Chapter 9: Defining Professionalism: Credentials, Ethics, and the PRO Difference

(My Promise of Certification, Master Licensing, and Transparency) - Chapter 10: Conclusion: Your Next Step to a Safer, More Comfortable Home

Chapter 1: The Dual Advantage: Why NoVA Needs PRO Electric plus HVAC

1.1. My Story: From Apprentice to Master of Two Trades

Let me be absolutely clear about one thing: I am not just a technician. I am a lifelong resident of Northern Virginia, and I have grease, solder, and insulation dust under my fingernails from every county in our region: Fairfax, Loudoun, Arlington, and Prince William.

More importantly, I am a Master Electrician and HVAC Professional. And I wear both titles with pride because I believe, fundamentally, that you can’t truly be an expert in one trade in this region without mastering the other.

My career didn’t start that way. I began on the electrical side, running conduit, wiring panels, and troubleshooting circuits. I often found myself on job sites where the HVAC crew was struggling. They’d curse a brand-new AC unit that wouldn’t power up, blaming the manufacturer or the installation. I’d walk over, check the dedicated breaker, tighten a loose lug connection in the panel, or replace a faulty low-voltage transformer, and suddenly, their $10,000 unit would purr to life.

A few years later, when I dedicated myself to the HVAC trade, the script flipped. I’d be servicing a furnace that was short-cycling, only to find that the cause wasn’t the gas valve or the control board, but an aging, overloaded electrical panel drawing brown-out voltage. The HVAC system was drawing too much power, straining the old connections until they failed.

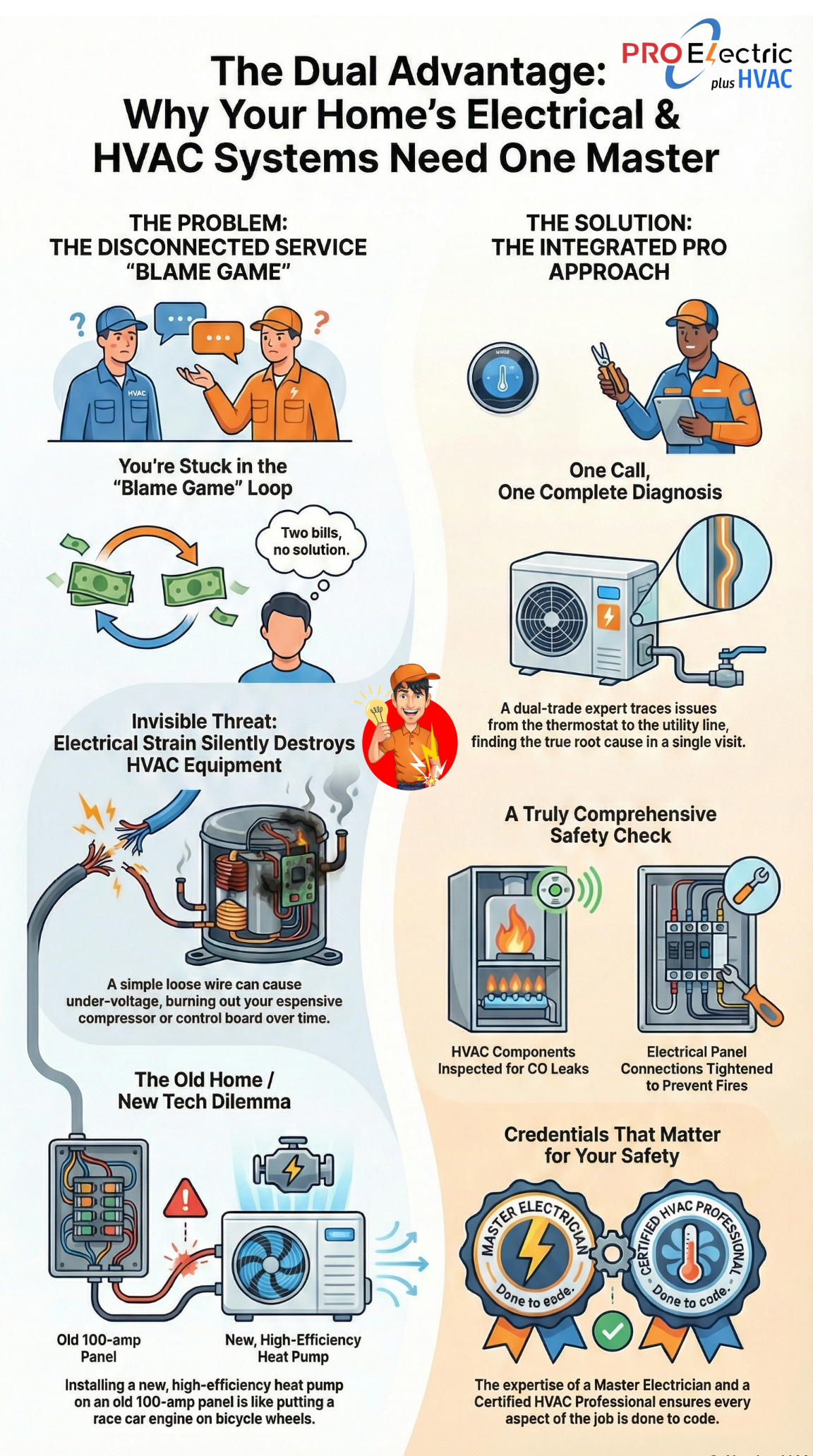

I got tired of the finger-pointing. I got tired of watching homeowners in Alexandria pay two separate service call fees, one to the HVAC guy who said, “It’s electrical,” and one to the electrician who said, “No, it’s your compressor.” That’s when the vision for PRO Electric plus HVAC was born: a single, seamless service in which the electrical and mechanical systems are treated as the integrated, interdependent systems they actually are. That is my core promise to you.

1.2. The Northern Virginia Weather Gauntlet

If you live here, you know we don’t have mild weather. We have extremes. Our systems do not get a break.

Consider the brutal, swampy humidity of a Fairfax County July. Your air conditioner isn’t just fighting the heat; it’s fighting moisture. It is running full-tilt, sometimes for days, drawing a massive, continuous electrical load. Then, a few months later, we plunge into the frigid air sweeping down from the mountains, forcing your furnace or heat pump into a relentless, high-BTU war against the cold.

This constant, high-demand cycling—from maximum cooling load to maximum heating load puts an incredible strain on every component: the compressor, the furnace blower motor, the control board, and, critically, the electrical circuits that power them. Systems in NoVA fail faster, work harder, and cost more to run than almost anywhere else because of these aggressive weather swings. You need a maintenance plan explicitly built to handle this regional stress, and that plan must be executed by someone who understands both the refrigerant pressure and the dedicated circuit amperage.

1.3. The Old Home/New Tech Dilemma

Northern Virginia is a patchwork of history and hyper-modernity, and that’s a massive challenge for your home’s infrastructure.

Drive through Arlington or Old Town Alexandria, and you’ll see charming, historic homes. Many of these beautiful houses still have 100-amp electrical panels, or worse, original wiring like Knob & Tube, which was never designed to run a modern, high-efficiency, multi-stage air conditioner or a new electric car charger. When I install a powerful new heat pump in a historic home, my first move is often to upgrade the panel to 200 amps because the new equipment cannot run safely or efficiently without stable, sufficient power.

Conversely, look at the sprawling new developments in Loudoun and Prince William Counties. These homes are massive, demanding multi-zone HVAC systems, often with pool heaters, complex lighting, and large appliances, all fighting for power. While the panels are usually 200-amp, the demand is so high that specialized, dedicated circuit installations are crucial to prevent nuisance trips and, more importantly, equipment damage.

The point is this: Your new HVAC system is only as good as the electricity powering it. If you put a Formula 1 engine (a high-SEER heat pump) into a frame with bicycle wheels (an old, overloaded electrical panel), you are going to crash. My job is to ensure the entire vehicle is built to perform.

1.4. Seamless Service, Zero Blame Game

This brings me to the very heart of my professional philosophy. Why does the conventional model fail?

It’s the Blame Game.

- You call the HVAC company: They say your furnace isn’t getting power. They charge you a service fee, pack up, and tell you to call an electrician.

- You call the electrician: They check the breaker, say there’s power, and tell you the problem is a faulty control board or blower motor—a component they don’t fix. They charge you a service fee and tell you to call the HVAC company back.

You, the homeowner, are stuck as the frustrated, out-of-pocket mediator. This nightmare scenario is what I swore to eliminate.

When you call PRO Electric plus HVAC, you get a master diagnostician who can trace the issue from the thermostat all the way back to the utility service line. If your AC fails, I’m checking the compressor, the coils, the charge, the run capacitor, the circuit breaker, the low-voltage wires, and the panel connections—all in one visit. That is seamless integration. That is what I call the Dual Advantage, and it saves you time, money, and the immense frustration of unnecessary back-and-forth.

1.5. A Personal Commitment to Our Local Community

I don’t just service these communities; I live here. When I’m in a service van in the HOV lane, I’m thinking about the local traffic, the local codes, and the local families. My reputation is built one house at a time, from the small bungalows of Clarendon to the sprawling estates near Middleburg.

This deep local knowledge is critical. We know which utility companies service which areas, how to handle the permitting process in each distinct county and city (which vary significantly!), and where to source parts quickly to minimize downtime. We understand the specific regional issues, such as the high iron content in well water that can affect plumbing connected to radiant systems, and the prevalence of certain environmental factors (like local tree pollen) that necessitate a focus on Indoor Air Quality solutions. We are your neighbors, committed to your year-round safety and comfort.

1.8. The Invisible Threat: Electrical Strain on HVAC Components

Here is a serious safety and financial warning that many single-trade technicians miss.

Your compressor and your blower motor are costly, high-tolerance mechanical components. They rely on clean, stable voltage to operate efficiently. A loose wire, a corroded connection point in an old panel, or a slight overload on a shared circuit can cause what we call “brown-out” or “under-voltage” conditions.

The HVAC system will try to compensate, but this electrical strain creates excessive heat and stress. Over time, that slightly low voltage can burn out the contactor, fry the main control board, or kill the compressor. What started as a simple, $10 electrical issue can turn into a $4,000 HVAC replacement. As an electrician, I treat your system’s power with the respect it deserves, ensuring it is properly grounded, protected, and fed with clean, stable electricity—which is the single most effective way to extend the lifespan of your expensive HVAC equipment.

1.9. Initial Safety Check: A Warning to the Homeowner

Before we dive deeper into this guide, I want to give you an immediate, actionable safety tip. Go to your electrical panel right now.

- Listen: Do you hear any persistent, loud humming, buzzing, or sizzling? This is often a sign of a loose connection or an overloaded breaker and should be looked at immediately.

- Look: Is the paint on the metal panel door discolored or bubbled? Do you smell a faint scent of burnt plastic or fish (a classic sign of overheated electrical insulation)?

- Feel (Carefully!): Do any of the breaker switches feel warm to the touch?

If the answer to any of these is yes, stop what you are doing. Do not delay. This is a potential fire hazard. This isn’t a sales pitch; this is me, the Master Electrician, telling you to prioritize safety.

1.10. The PRO Electric plus HVAC Mission Statement

The chapters that follow are a Master’s course in home ownership for Northern Virginia. We are going to cover everything from the massive efficiency gains of modern heat pumps to the critical need for whole-home surge protection and standby generators. We will discuss specific troubleshooting for the “No Heat” call and the essential checklist for our annual preventative maintenance.

Our mission is simple: To provide Northern Virginia homeowners with the safest, most efficient, and most comfortable home environment possible through the seamless integration of Master-level electrical and HVAC services.

We are not just fixing systems; we are optimizing your entire home infrastructure. It is time to stop worrying about which tradesperson to call and start living in a home that performs exactly as it should. Let’s get started.

↑ Go back to Table of Contents

Chapter 2: Achieving Climate Mastery: Core HVAC Systems & NoVA’s Demands

2.1. The Air Conditioning Reality of NoVA Summers

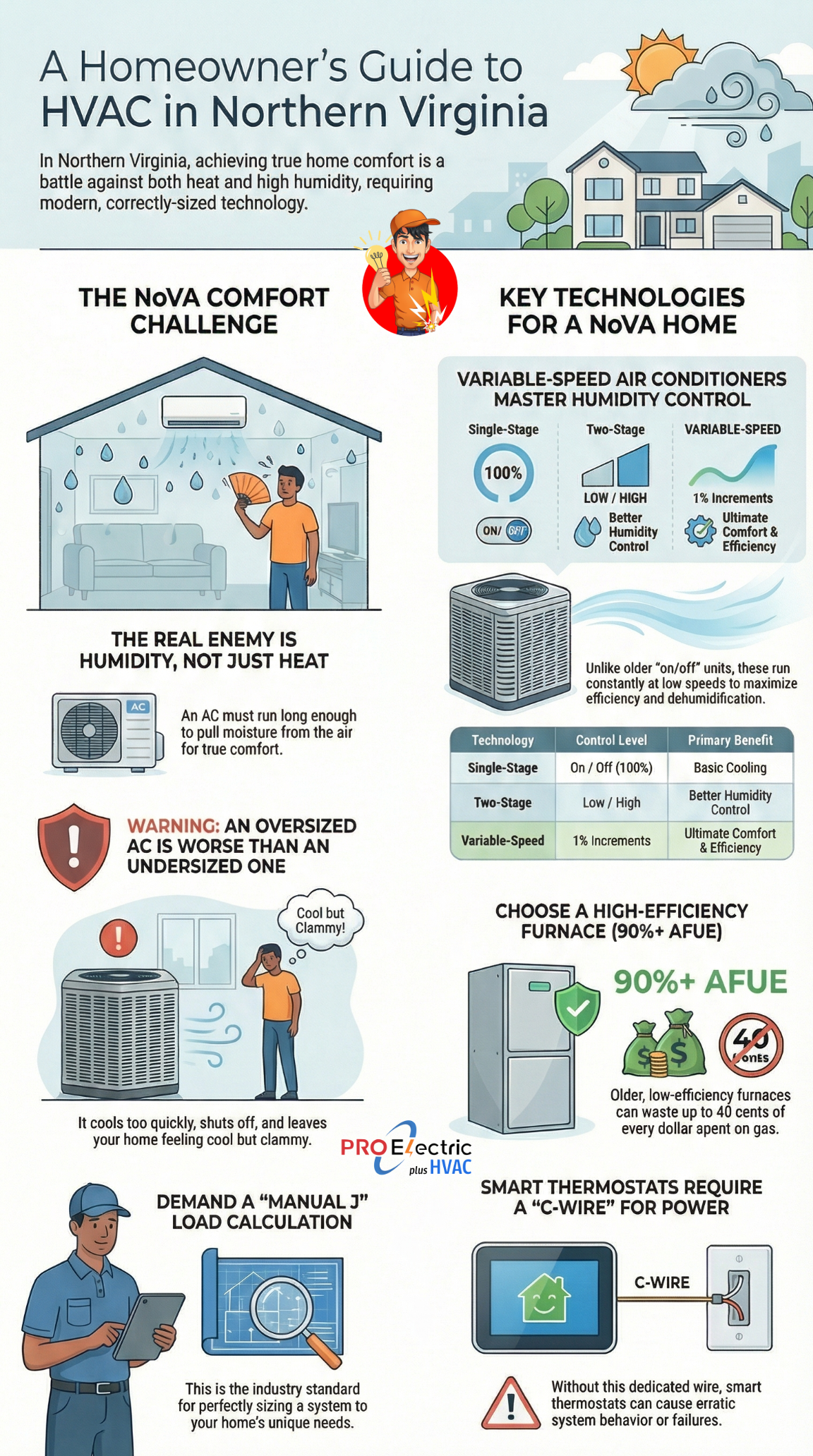

When a homeowner in Loudoun or Prince William calls me in July, they aren’t just hot; they’re often frustrated by a system that simply can’t keep up with the overwhelming moisture and heat we experience. Here in Northern Virginia, your air conditioner is a combat veteran fighting two battles: sensible heat (temperature) and latent heat (humidity).

This is why merely *cooling* the air isn’t enough. True comfort requires a well-sized system that runs long enough to pull that oppressive moisture out of the air. This brings us to efficiency and technology. You’ve likely heard of SEER (Seasonal Energy Efficiency Ratio), and now the new standard, SEER2. Forget the old 10 or 13 SEER units; for our climate, I am strongly advocating for units in the 16+ SEER2 range. The initial cost is higher, yes, but the year-over-year savings on Dominion or PEPCO bills—plus the sheer comfort they provide—make them an investment, not an expense.

More critical than the rating, however, is the compressor type.

- Single-Stage: On or Off. 100% capacity or 0%. Old technology, poor comfort control, and high energy spikes.

- Two-Stage: Low (typically 60-70%) or High (100%). Better at handling humidity by running longer in the low stage.

- Variable-Speed/Inverter Technology: The game-changer. These units can ramp up and down in tiny increments (often 1% steps, from 30% to 100%). They run nearly constantly at lower, super-efficient speeds, which is the absolute best way to dehumidify your home and keep the temperature perfectly stable. As both an Electrician and HVAC Pro, I love these because their inverter technology is electrically stable and puts less stress on the home’s wiring.

2.2. Gas Furnaces: The Workhorse of the Winter

When the cold snaps hit Arlington or Alexandria, the gas furnace is the heating hero for many of us. But not all furnaces are created equal. The key rating here is AFUE (Annual Fuel Utilization Efficiency). It’s a measure of how much of the gas used turns into usable heat versus what goes up the flue.

- Low-Efficiency (60-80% AFUE): These are the units you find in many older homes. For every dollar you spend on gas, 20-40 cents are wasted.

- High-Efficiency (90%+ AFUE): These furnaces capture the exhaust heat through a secondary heat exchanger and condense the moisture, routing the cool condensate water out through a PVC pipe. For a homeowner committed to efficiency in NoVA, I strongly recommend a 90%+ model. The energy savings are undeniable, but they introduce a new complexity—the need for a condensate pump and drain, which requires its own electrical supply and safety interlocks.

2.3. The Electrical Side of Heating: Ignitors and Blowers

Here is where my two trades intersect every single time a furnace is serviced. A furnace is a large, complex electrical appliance that *uses* gas as its fuel source.

- The Ignition System: Older furnaces use a pilot light, which is a tiny, persistent flame. Newer ones use a Hot Surface Ignitor (HSI)—a ceramic part that glows white-hot to light the gas. An HSI is a critical electrical component. If the voltage is low, or if the board is failing, the HSI won’t get hot enough, and the safety controls will shut the system down. My job is to determine whether the HSI itself has failed (an HVAC component) or whether the transformer or control board is failing to deliver the correct power (an electrical component).

- The Blower Motor: This is a heavy-duty electrical motor that moves air through your ductwork. In a gas furnace, the blower will not kick on until the heat exchanger is at a safe temperature. In a high-efficiency system, the Variable Speed Blower Motor (VSBM) is a marvel of technology. It can speed up or slow down based on demand, which is phenomenal for comfort and quiet operation. However, the VSBM also requires a complex electrical signal and is extremely susceptible to voltage surges and spikes. I check the amperage draw of the blower motor on every service call; if it’s pulling too many amps, the motor is failing, and a new one is needed before it trips the breaker for good.

2.4. Boiler Systems: Still a Force in Older Homes (Especially Arlington & Alexandria)

I see beautiful, robust boiler systems almost every day in the historic districts of Arlington and Alexandria. These systems—radiant heat—provide a gentle, even heat that many homeowners prefer. While they don’t have the high-volume electrical load of a blower motor, they have their own set of electrical complexities:

- Circulator Pumps: These are small, constantly running electrical pumps that circulate hot water through baseboards or radiators. In zoned systems (which are common), you’ll have multiple pumps, each drawing power.

- Zoning Controls: Boilers often utilize zone valves or multiple thermostats, each demanding low-voltage wiring and integration with a central control board.

- Gas Valve and Pilot Controls: Safety controls on a boiler are critical, requiring a stable electrical input to ensure proper operation.

My electrical expertise is essential here, as the wiring on these older systems can be brittle or confusingly routed.

2.5. Why Proper Sizing is Non-Negotiable (The BTUs, Tons, and Load Calculation)

I cannot stress this enough: Sizing your HVAC system correctly is the most important decision you will make. Period.

A contractor who just says, “The old one was 3 tons, so you need a 3-ton replacement,” is doing you a massive disservice. Homes change! We add insulation, replace windows, finish the basement, and install LED lighting—all of which change the heat load.

I follow the industry standard known as Manual J Load Calculation. This highly detailed, room-by-room, exposure-by-exposure math determines the precise amount of heating (in BTUs) and cooling (in Tons) your home needs.

- The Danger of Oversizing: An oversized AC unit is worse than an undersized one. It cools the air too quickly, satisfies the thermostat, and shuts off (short-cycles) before it can run long enough to dehumidify the air. The result? A home that is cool but clammy, sticky, and uncomfortable, with a system that is constantly starting and stopping, leading to premature component wear.

- The Danger of Undersizing: A unit that never stops running, constantly trying to reach the setpoint. It wastes energy and burns out the compressor faster.

I use my knowledge of your home’s electrical demands to advise on this, too. A slightly larger, high-efficiency system may require a slightly heavier gauge wire or a dedicated breaker, which I am perfectly qualified to handle from start to finish.

2.6. Humidity Control: The Unsung Hero of Comfort

As I mentioned earlier, humidity is the silent killer of comfort in our region. If your thermostat is set to 75°F but the relative humidity is 65% or higher, you are going to feel miserable.

While a properly sized variable-speed AC will help, many NoVA homes benefit immensely from a whole-home dehumidifier integrated directly into the HVAC system. This is a separate appliance that runs independently of the cooling cycle and only removes moisture.

From an electrical perspective, this requires its own power supply, its own control wiring, and sometimes a dedicated circuit. I’ve installed countless dehumidifiers in the damp basements of Prince William and the shaded, moisture-prone areas of Loudoun, and the homeowner feedback is always the same: a profound difference in comfort.

2.7. Refrigerant Leaks: The Silent Killer of Efficiency

Refrigerant is the lifeblood of your AC or heat pump. It is the medium that absorbs heat indoors and releases it outdoors. It does not get “consumed” like gas—it operates in a closed loop. If your system is low on refrigerant, it means you have a leak.

Any contractor who simply “tops you off” without finding and fixing the leak is acting irresponsibly. It’s an illegal venting of a potent greenhouse gas, and it guarantees you’ll be calling them back in a year.

My process involves a meticulous search for the leak (using UV dye, sniffer tools, or even bubbles) in the coils, line set, or connections. Once found, we recover the old refrigerant, professionally repair the leak by brazing the copper line, evacuate the system to a vacuum, and recharge it with the precise weight of refrigerant required. The cost of refrigerant has skyrocketed, so fixing the leak is more financially prudent than ever.

2.8. Understanding the Thermostat (The Brain of the System)

The modern thermostat is a complex computer, not just a switch. With the rise of smart, Wi-Fi-enabled thermostats (Nest, Ecobee, Honeywell T-series), the electrical demands have changed.

- The “C” Wire (Common Wire): Smart thermostats require constant low-voltage power to run their screen and Wi-Fi chip. Many older homes only have four wires running to the thermostat, but the smart thermostat needs a fifth—the C-wire. As the electrical specialist, I often have to run this new wire or install a transformer/adapter kit at the control board. If this C-wire connection is flaky, the thermostat will try to “steal” power, which can lead to it short-cycling the HVAC system or causing erratic behavior. This is a classic example of an electrical problem that manifests as an HVAC failure.

My role is to ensure your “brain” is properly powered, programmed, and communicating perfectly with the “heart” (the control board) and the “muscles” (the motors and compressor).

2.9. Indoor Air Quality (IAQ) and NoVA Allergies

If you suffer from the seasonal allergies prevalent in the D.C. area, or if you live in a tighter, modern home, IAQ is paramount. We focus on two key areas:

- Air Filtration: Moving beyond the cheap MERV 8 filters to MERV 11-13 filters, or installing media filters (4-5 inches thick) that dramatically increase the surface area for capturing fine particulates, dust, and pollen.

- Air Purification: Installing UV (Ultraviolet) Lights inside the air handler to sterilize mold, bacteria, and viruses on the wet evaporator coil, or installing Whole-Home Air Purifiers (like the REME-HALO) that actively clean the air as it circulates through the ducts.

These IAQ solutions are all electrical add-ons. They require a dedicated wiring tie-in, often to the furnace control board, and sometimes a separate transformer. As your Master Electrician, I ensure they are safely wired to code and interlocked with the blower motor so they only operate when air is flowing.

2.10. Case Study: The Loudoun County Mansion vs. The Arlington Row House

To illustrate the complexity we manage:

- Loudoun County Mansion: This home is 8,000 sq. ft., two-zone cooling, gas heat, a whole-home dehumidifier, and a new Level 2 EV charger in the garage. The electrical service is a robust 400 amps, but the sheer number of high-load appliances requires careful load balancing across the two 200-amp panels. The HVAC challenge is ductwork and zoning for large, open-concept rooms. My expertise is integrating the three separate HVAC systems with the dozens of electrical circuits so they can all run simultaneously without a voltage dip.

- Arlington Row House: This home is 1,800 sq. ft., but it’s three stories with a flat roof. It often features a boiler/radiant system for the first floor and a high-velocity Mini-Split system (which we’ll cover in the next chapter) for the top two floors. The electrical panel is 100 amps, maxed out. My challenge is to upgrade the 100-amp service to 200 amps in a tight space while running new electrical lines for the heat pump condenser and ensuring the aging boiler components are also safe.

No matter the size or age of your Northern Virginia home, the solutions we provide are rooted in the integrated, professional mastery of both electrical and mechanical systems a proper, full-system approach to comfort.

↑ Go back to Table of Contents

Chapter 3: Powering the Modern Home: Essential Electrical Safety and Capacity

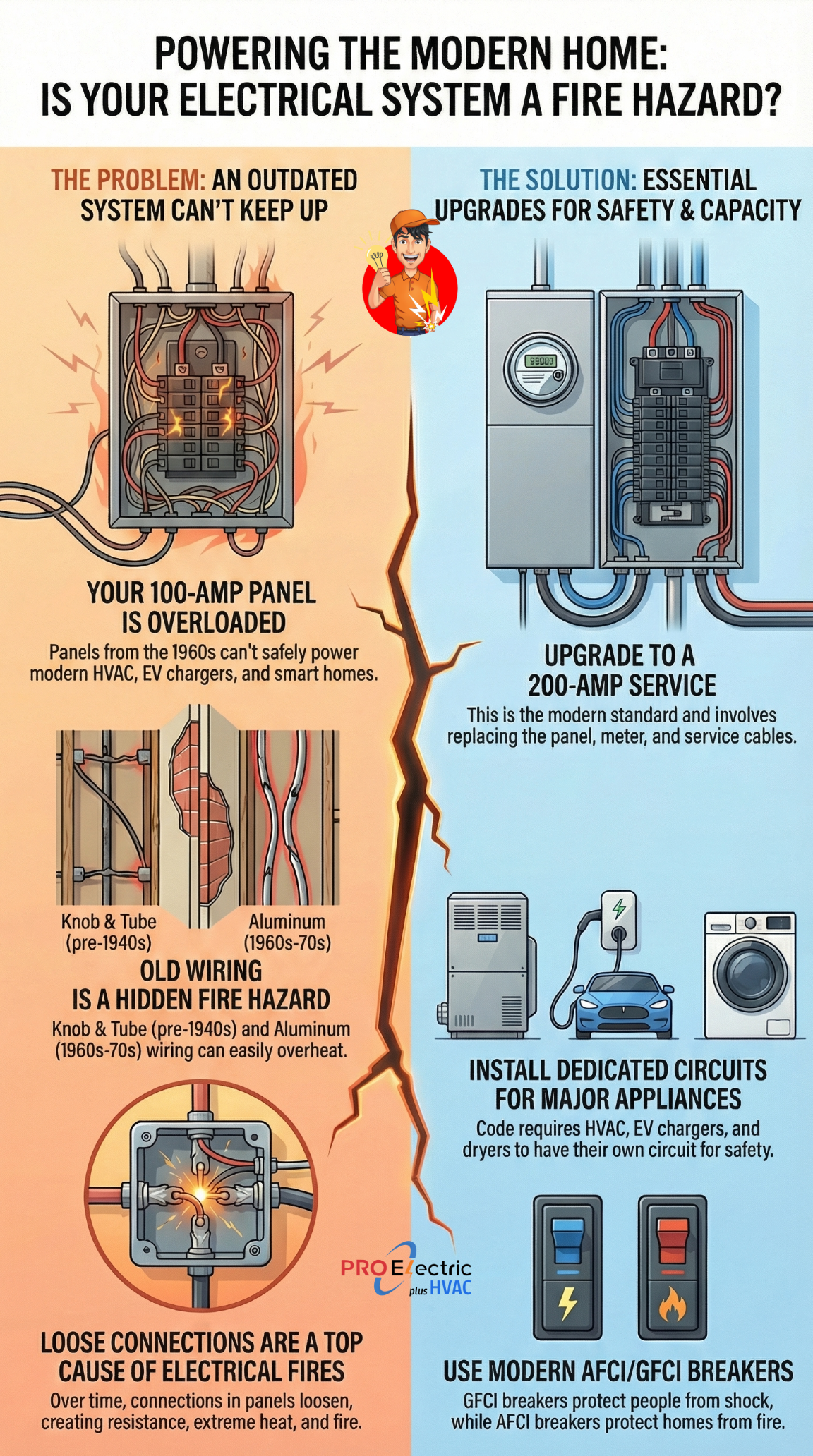

3.1. The Panel: Your Home’s Electrical Heart (And Why Yours Might Be Too Small)

Think of your electrical panel as the heart of your home. It receives the main line power from the utility company (Dominion or PEPCO) and then distributes it through a maze of arteries (circuits) to every light, outlet, and appliance.

In Northern Virginia, especially in the older, established neighborhoods of Fairfax and Arlington, I see 100-amp panels every single day. One hundred amps was perfectly sufficient for a home in 1965 when the biggest electrical draws were a stove, a water heater, and a small central AC unit.

But the American home has fundamentally changed. We now have:

- High-efficiency, but power-hungry, Variable Speed HVAC Systems (which we discussed in Chapter 2).

- High-speed Level 2 EV Chargers.

- Tankless Water Heaters.

- Dozens of computers, high-definition TVs, and complex smart home systems.

- Standby Generators (which require a transfer switch wired *into* the panel).

The simple truth is that a modern NoVA home cannot function safely or efficiently on a 100-amp service. Trying to force a 21st-century lifestyle onto a 20th-century panel is a recipe for disaster—overheating wires, tripping breakers, and, potentially, fire.

3.2. Panel Upgrades: 100-Amp vs. 200-Amp—The Non-Negotiable Decision

When I assess a home, I use a rigorous electrical load calculation to determine the *minimum* amperage required. Nine times out of ten, my recommendation for any homeowner contemplating a major HVAC replacement or future home improvements is a shift to 200-amp service.

A panel upgrade is not just about replacing the metal box. It is a complex, multi-stage, code-critical job that involves:

- Utility Coordination: Working with the power company to temporarily disconnect the service.

- The Service Entrance Cable: Replacing the main wire (the ‘mast’) that runs from your meter to the weatherhead—it must be sized for the 200-amp service.

- The Meter Base: Ensuring the meter socket can handle the higher load.

- The Grounding System: Installing new grounding rods and connections to ensure a safe path for fault current.

This is a job for a Master Electrician, period. A mistake here is not just inconvenient; it can be catastrophic. When I install your new, power-demanding AC unit or heat pump, upgrading the panel is part of the integrated plan to ensure that unit will have the capacity and stability to run for the next 15-20 years.

3.3. The Dangers of Outdated Wiring (Knob & Tube and Aluminum) in Older NoVA Homes

In the pre-war homes of Arlington and the older parts of Fairfax, I still find relics of a different time:

- Knob & Tube Wiring: Used up until the 1940s, this system has no safety ground wire, and the insulation is often brittle. Most critically, it was designed to run in open air. When a homeowner blows insulation into the walls (which is good for HVAC efficiency!), they unintentionally bury the K&T wiring, causing it to overheat and become a severe fire hazard.

- Aluminum Wiring: Used for a brief period in the 1960s and 70s due to the high cost of copper. Aluminum wiring expands and contracts much more than copper, leading to loose connections at outlets, switches, and the panel itself. Loose connections create resistance, and resistance creates heat. Heat leads to fire.

As a Master Electrician, my primary responsibility is safety. If my HVAC assessment reveals a plan to install a high-load unit, and I see these wiring issues, my professional and ethical obligation is to address them first. We’re not just swapping wires; we are often rewiring the entire house to current code for safety.

3.4. Dedicated Circuits: Why Your AC and Furnace Need Their Own Line (It’s the Law!)

This is one of the most common shortcuts I see homeowners attempt, and it always causes problems. Every major appliance in your home, especially HVAC equipment, needs a dedicated circuit.

What does that mean? It means the circuit breaker in the panel and the wiring leading from it only go to that single appliance—*nothing else*.

- Your outdoor AC Condenser needs a dedicated 240V circuit.

- Your furnace/air handler needs a dedicated 120V circuit (and often a second one for a humidifier or UV light).

- Your electric water heater needs a dedicated 240V circuit.

- Your new EV charger needs a dedicated 240V circuit.

Why?

- Code Compliance: It’s required by the National Electrical Code (NEC) for safety.

- Performance: HVAC motors experience high starting loads (inrush current). If a system is sharing a circuit with your garage lights or a power tool, that sudden surge can trip the breaker, or worse, cause a voltage dip that prematurely damages the HVAC component.

When PRO Electric plus HVAC installs your new system, we install the correctly sized wire and breaker that is 100% dedicated to that unit. It’s part of the complete package—not an afterthought.

3.5. Understanding Arc Fault and Ground Fault Circuit Interrupters (AFCI/GFCI)

The electrical code is constantly evolving to make our homes safer, and AFCI and GFCI protection are now mandatory in almost every new residential circuit.

- GFCI (Ground Fault Circuit Interrupter): Protects against shock by sensing an imbalance in the current (meaning electricity is escaping to the ground, possibly through a person). You see these in kitchens, bathrooms, garages, and outdoors.

- AFCI (Arc Fault Circuit Interrupter): Protects against fire by sensing an erratic electrical signature, or arc, that is characteristic of dangerous, loose, or damaged wiring—the precursor to a fire.

While AFCI is not always required for dedicated major appliances, I install them where appropriate, and I always ensure that any general use circuit near your mechanical room is properly protected. The safety provided by these modern breakers is non-negotiable in a PRO installation.

3.6. Electrical Code Compliance in Fairfax, Loudoun, and Beyond

There is a patchwork of local regulations in Northern Virginia. Fairfax, Loudoun, Arlington, and Prince William all adopt the National Electrical Code (NEC), but they also have their own local amendments and permitting processes.

When you hire a cheap, unlicensed contractor, they are cutting corners by avoiding the permit process. The result? A system that hasn’t been inspected by the county and may contain serious, hidden flaws that violate code.

As a Master Electrician, my commitment is to pull the proper permits for all major work (panel upgrades, generator installs, new HVAC system wiring). This serves two purposes:

- Safety: It forces an independent county inspector to verify that my work is safe and to code.

- Home Value: It provides a paper trail for the next homeowner, proving that the work was done professionally and legally.

Your investment in your home should not be compromised by cheap, illegal work. The peace of mind that comes with a county-stamped approval is priceless.

3.7. The Heavy Load of Kitchens and Laundry: A Hidden Drain on Your System

It’s easy to focus on the big draws—the HVAC and the electric car. But I want to remind you that your everyday life is often the reason your panel is overloaded.

- Kitchens: Electric ovens, cooktops, microwaves, and multiple small appliances (toasters, blenders) draw an incredible amount of power.

- Laundry: Electric dryers are a huge 240V load, and modern high-efficiency washers, while energy-friendly, still require stable power.

When I plan an upgrade or troubleshoot a system, I look at the whole picture. I ensure that the HVAC is protected and that the dedicated circuits are correct, but I also make sure your family can run the AC, the washing machine, and the oven all at the same time without blowing the main breaker. This holistic load management is a core part of the PRO Electric plus HVAC service.

3.8. The Fire Hazard: Frayed Wires, Loose Connections, and Breaker Overload

Let me tell you about the most common danger I encounter in old NoVA homes—loose connections.

Over decades, the constant heating and cooling of the wire and the daily vibration from your home (especially from motors like your furnace blower or AC compressor) cause terminal screws and lug connections inside the panel to loosen. This creates a tiny gap—a point of resistance. Resistance creates heat. The metal melts, the plastic insulation burns, and the resulting fire can start inside the wall or in the panel itself.

As part of my preventative maintenance (which we will detail in Chapter 7), I make it a practice to thermographically scan and physically tighten all major lugs and breaker screws. This simple electrical maintenance task is critical for safety and system longevity, and it’s something your average single-trade HVAC tech would never touch.

3.9. Meter Base and Service Entrance Cable: The Oft-Forgotten Upgrade

When you upgrade your panel, the meter base (where the meter plugs in) and the service entrance cable (the thick wires coming into the house) must also be upgraded to handle the higher amperage. This is outdoor work, often involving ladders and utility disconnects, and it’s a high-risk electrical job.

A poorly installed service cable or meter base can leak water into your panel, leading to rust, corrosion, and catastrophic failure. I see too many “handyman” or under-qualified electrical outfits cut corners here. I view the meter base as the first line of defense for your entire electrical system, and its installation must be perfect, sealed against the elements, and fully compliant with the utility company’s standards.

3.10. Case Study: The Prince William Panel Meltdown I Fixed Last Winter

I got a frantic call from a homeowner in Prince William County last winter. Their house smelled faintly of burnt plastic, and their furnace was completely dead.

When I arrived, the issue was immediately clear to me as a Master Electrician. The main lug (the large bolt where the main power enters the panel) for one leg of the 240V service was severely corroded and burnt. The loose connection had caused extreme heat, which had melted the plastic coating of the adjacent wires and destroyed the main breaker. The furnace, which had been drawing its power from that leg, had simply shut down due to a power spike/failure.

The HVAC unit wasn’t the problem—the electrical system was. We had to perform an emergency full panel and meter base replacement, coordinate the power disconnect, and then, only *after* the home was safe, did we check and replace the furnace’s low-voltage transformer, which had been fried in the event. If that homeowner had called an HVAC-only company, they would have replaced the low-voltage transformer, it would have immediately failed again, and the fire hazard would have remained in the panel. The integrated PRO approach saved their house from a serious fire.

↑ Go back to Table of Contents

Chapter 4: The Strategic Edge: Heat Pumps, Mini-Splits, and Local Rebates

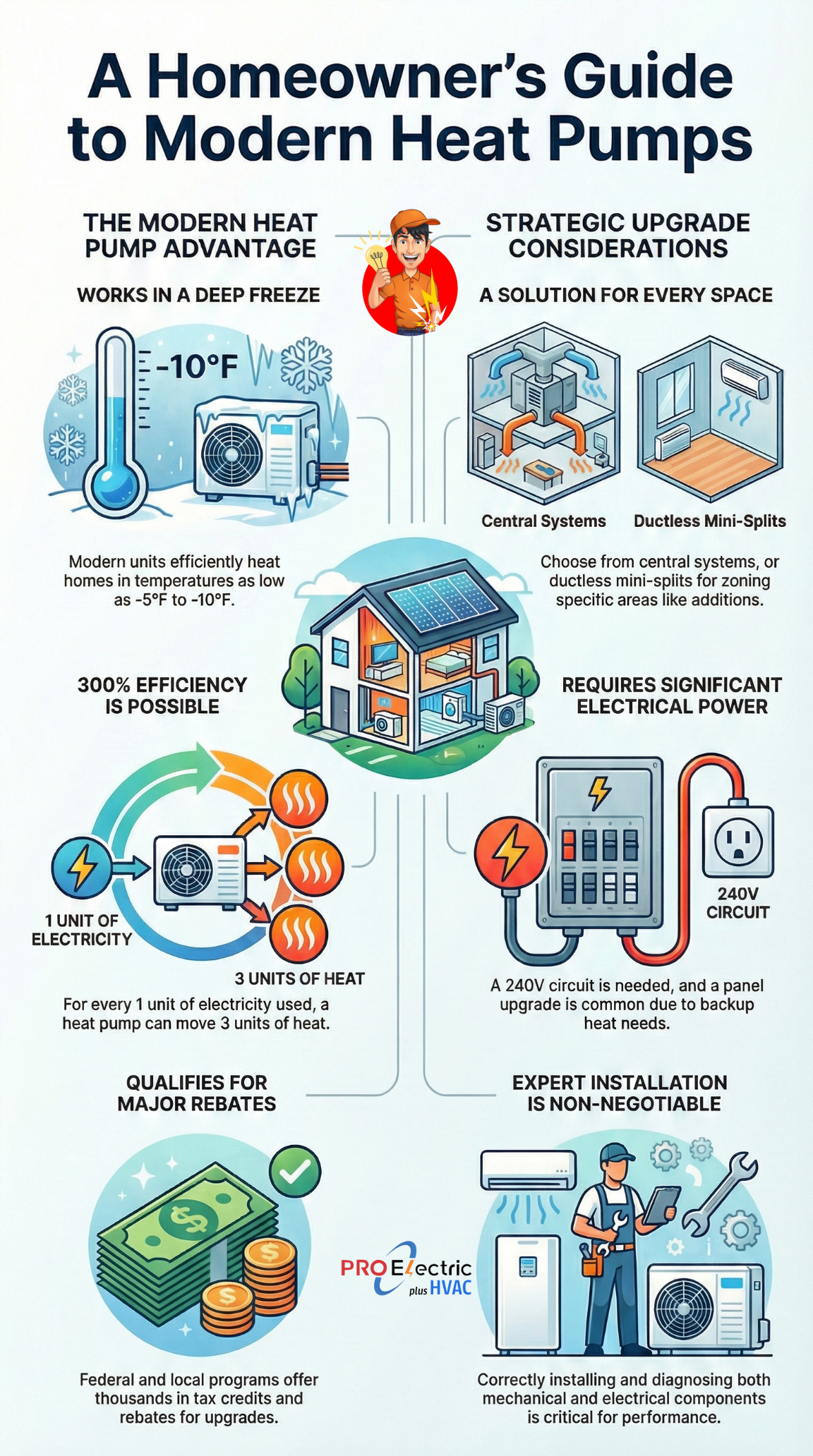

4.1. Debunking the Myths: Modern Heat Pumps Are No Longer Just for the South

For decades, the perception in Northern Virginia was that a heat pump was a great AC unit, but you absolutely needed a gas furnace to handle our harsh, unpredictable winters. I’m here to tell you that this thinking is obsolete.

Modern, high-efficiency heat pumps, especially those using variable-speed (inverter) technology, are game-changers for our region. They can extract heat from outdoor air down to temperatures well below freezing, often down to -5°F or -10°F with remarkable efficiency. They don’t *make* heat like a furnace; they *move* it, and moving heat is dramatically more energy-efficient than creating it through combustion (gas) or resistance (electric strips).

For a homeowner in Fairfax or Loudoun looking to reduce their carbon footprint, eliminate their gas bill, and consolidate their mechanical systems, a modern heat pump is the single best investment. They are, however, a more complex installation that requires an expert who understands both the refrigerant cycle and the heavy-duty electrical components.

4.2. Understanding HSPF and COP: The Efficiency Metrics That Matter

Just as you learned about SEER2 for cooling and AFUE for heating, heat pumps have their own metrics that matter deeply in a four-season climate like ours:

- HSPF (Heating Seasonal Performance Factor): This is the measure of the efficiency of the heat pump in heating mode over a season. The higher the number, the better. I look for units with an HSPF of 10.0 or higher for maximum winter performance.

- COP (Coefficient of Performance): This is a ratio comparing the heating output to the energy input at a *specific temperature*. A COP of 3.0 means the unit provides 3 units of heat for every 1 unit of electricity consumed—an incredible feat of efficiency.

When I recommend a heat pump, I am looking at its performance curve, specifically its efficiency at 17°F and 5°F, which are common temperature benchmarks for our coldest snaps. The units I install are rated to provide real, comfortable heat without relying on costly emergency “strip heat” until absolutely necessary.

4.3. Heat Pump Defrost Cycle: The Critical Process I Need Homeowners to Understand

Heat pumps, by their nature, must make the outdoor coil colder than the outdoor air to absorb heat. In cold, humid conditions, moisture in the air will freeze onto the coil. If left alone, this ice would turn the unit into a giant, useless block.

The Defrost Cycle is the system’s electrical solution:

- The system reverses the flow of refrigerant (like it’s cooling), sending hot gas to the outdoor coil to melt the ice.

- The outdoor fan shuts off to accelerate the melting.

- The indoor unit often engages the electric auxiliary heat to prevent the house from being blasted with a wave of cold air.

The defrost cycle is entirely driven by the electrical control board and sensors. If a sensor fails, or if the board is improperly programmed, the unit will either never defrost (turning into a block of ice) or defrost too often (wasting energy). My dual expertise allows me to immediately diagnose if the issue is a faulty pressure sensor (HVAC) or a relay failure on the control board (Electrical).

4.4. Mini-Splits: The Perfect Zoning Solution for Additions and Garages

In the dense neighborhoods of Arlington and the older, two-story homes in Fairfax, a common problem is a lack of ductwork or extreme temperature variations between floors. This is where ductless mini-split systems shine.

Mini-splits are essentially small heat pumps that service one to five zones (heads). They are perfect for:

- Finished Basements (especially in Prince William, which can be notoriously damp).

- Garage Conversions or Workshops.

- Home Additions or Sunrooms (where running new ductwork is impossible).

- Historic Homes that cannot accommodate bulky central ductwork.

The electrical requirements for mini-splits are unique. The large outdoor unit (condenser) requires a dedicated 240V circuit, and the communication between the outdoor and indoor heads is handled by complex low-voltage wiring. My integrated service ensures the outdoor unit has a clean power supply and that the electrical communication lines are protected and properly routed—often in visible spaces where aesthetics matter.

4.5. Electrical Requirements for Heat Pump Installation: A Technical Dive

Heat pumps are one of the highest electrical loads in the entire home. Even a modest 3-ton unit needs a dedicated 240V circuit, often served by a heavy 30-to-50 amp breaker. But the *Auxiliary Heat* (electric strip heat) can be even more demanding.

Auxiliary heat is your emergency backup. If the outdoor temperature is too low for the heat pump to operate efficiently, or if the unit goes into a long defrost cycle, the system turns on a bank of electrical coils that generate heat directly through resistance. This is very effective, but it is extremely expensive to run.

A typical auxiliary heat kit can draw 50 to 80 amps *on its own*. This means that the total electrical demand for the system can easily exceed 100 amps. If your existing panel is only 100 amps, installing this system without an upgrade is impossible and dangerous. My planning always includes a rigorous electrical load calculation to ensure your existing or new panel can handle the system’s maximum possible draw when the heat pump and the auxiliary heat are running simultaneously.

4.6. The Reversing Valve: When Your Heat Pump Is Stuck in the Wrong Season

The Reversing Valve is the mechanical heart of the heat pump. It’s a solenoid-driven valve that literally reverses the flow of refrigerant, changing the unit from cooling mode to heating mode (and vice versa).

If you call me in October and your heat pump is blowing cold air when the thermostat is set to “Heat,” the problem is often the reversing valve. As the dual-trade professional, I immediately check two things:

- Electrical: Is the low-voltage solenoid receiving the 24V signal from the control board to flip? If not, the problem is a faulty thermostat or control board.

- Mechanical: If the solenoid is getting the signal, has the valve mechanically stuck due to corrosion or a blockage? If so, the valve needs replacement (a specialized HVAC repair).

Without the electrical knowledge, a technician might unnecessarily replace the valve; without the HVAC knowledge, an electrician might replace the control board and leave the mechanically stuck valve behind. The PRO difference is the ability to nail the diagnosis the first time.

4.7. Navigating the IRA and Local Rebates: My Step-by-Step Guide to Saving Thousands

Here’s some great news: The federal and state governments are now offering massive incentives for Northern Virginia homeowners to upgrade to high-efficiency heat pumps. The Inflation Reduction Act (IRA) provides significant tax credits and rebates for these upgrades.

However, navigating the paperwork is confusing. I make it my business to be up-to-date on all local and federal programs, including those offered through local utilities like Dominion Energy.

My guidance includes:

- Identifying specific high-efficiency models that qualify for the maximum credits (often up to $2,000 in tax credits and thousands more in rebates).

- Ensuring the installation documentation meets the strict requirements for certification.

- Integrating the electrical work (like a panel upgrade) into the project, which often allows for additional incentives.

This strategic advice is part of the service. I don’t just sell you a unit; I help you maximize the financial benefit of the upgrade.

4.8. Geothermal: The Ultimate NoVA Solution (If Your Lot Allows It)

For the ultimate in long-term efficiency and comfort, especially on larger Loudoun or Prince William properties, Geothermal Heat Pumps are the gold standard. They use the earth’s stable temperature (around 55°F year-round) as the heat source and sink, making them incredibly efficient and eliminating the need for a separate furnace.

While the installation requires drilling and extensive piping, the core system is still a heat pump that requires a dedicated electrical line and complex control wiring. The initial investment is high, but the operating cost is dramatically lower, and the system longevity is superior. I provide consultations for these systems, ensuring the necessary electrical infrastructure is planned alongside the excavation.

4.9. The Critical Role of Auxiliary Heat (Electric Strips) and Load Management

As we touched on earlier, auxiliary heat is the safety net, but it is an *expensive* safety net. As the system manager, I program the control board to minimize its use.

- Proper Lockout Temperature: I carefully set the “lockout” temperature—the point at which the heat pump stops trying to be the sole source of heat and allows the auxiliary strips to kick in. For modern heat pumps, this is often set much lower than older units, saving the homeowner money.

- Sequential Staging: I ensure that if auxiliary heat *is* needed, the massive electrical coils kick on sequentially (in stages) to prevent one huge surge of power that can trip a main breaker or strain the utility line.

This is a combination of HVAC knowledge (setting the right temperature) and electrical knowledge (managing the electrical load), which is the very essence of the PRO advantage.

4.10. PRO’s Recommended Brands and Why We Choose Them for Northern Virginia

I am not beholden to any single manufacturer. My loyalty is to my customer and the Northern Virginia climate. The brands I recommend—typically those offering high-HSPF, variable-speed technology—are chosen because their components hold up against the dual stress of our summers and winters, and their electrical control boards are reliable.

I evaluate units based on:

- Reliability of the Inverter Drive: The heart of the variable-speed system.

- Warranty and Parts Availability: Critical for minimizing downtime in an emergency.

- Performance in Low Ambient Temperatures: A key spec for NoVA.

When you invest in a new heat pump or mini-split, you are investing in two decades of comfort. My recommendations are grounded in years of repairing and installing every major system in the toughest climate conditions our region offers.

↑ Go back to Table of Contents

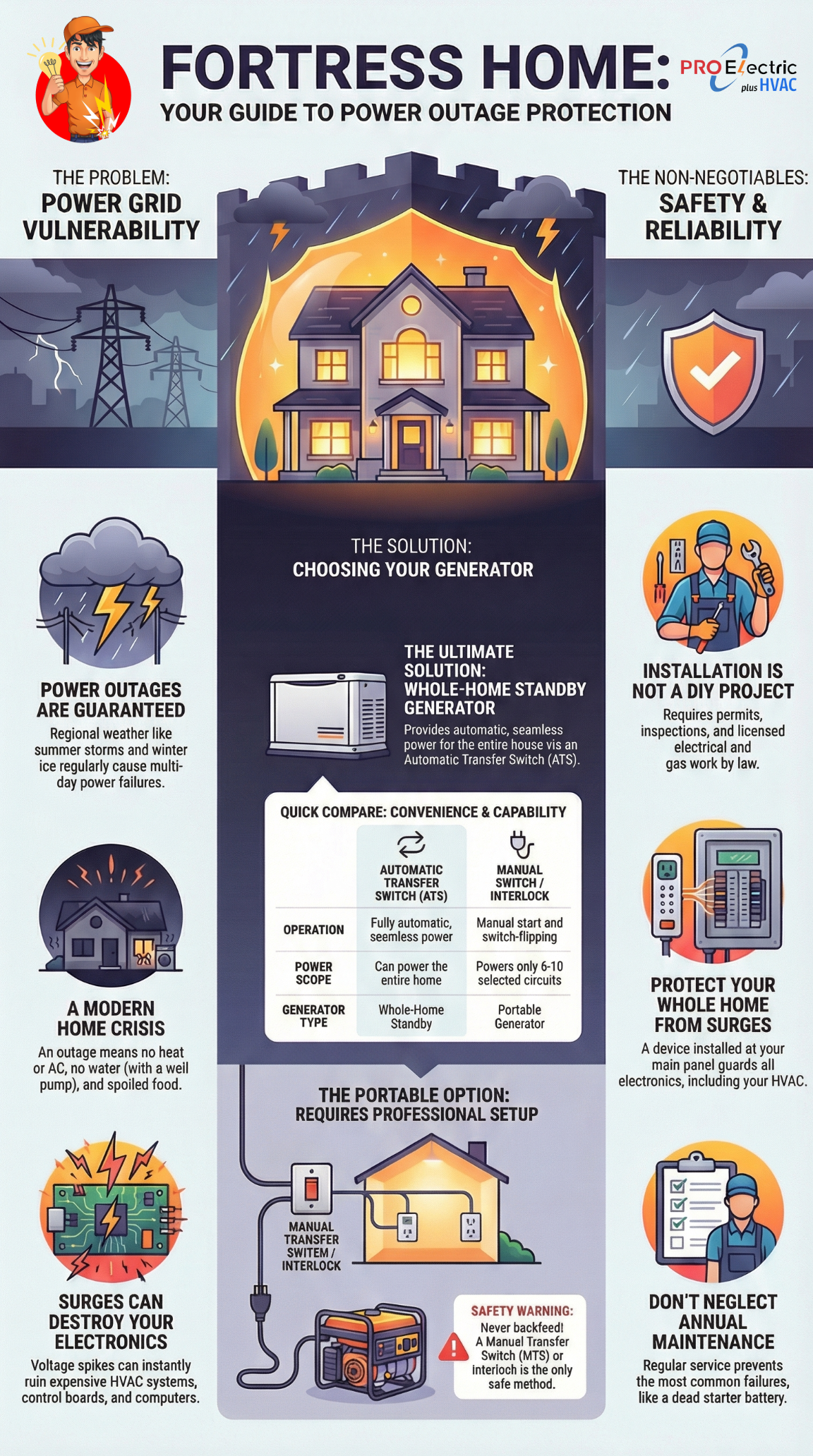

Chapter 5: Fortress Home: Generators, Power Outages, and Surge Protection

5.1. The Inevitable Outage: Why Every NoVA Home Needs a Backup Plan

If you have lived in Northern Virginia for any length of time, you know the power will go out. It is not a matter of *if*, but *when*.

Our region is constantly subjected to a rotating roster of weather-related power failures:

- Summer Derechoes: These massive wind storms in Prince William and Loudoun often snap large oaks, taking down power lines and leaving entire neighborhoods without power for days.

- Winter Ice and Snow: In Arlington and Fairfax, a heavy, wet snow will freeze, coating the utility wires and causing them to sag and break.

- Seasonal Tree Falls: Even a standard thunderstorm can bring down a tree and knock out power, especially in our heavily wooded suburbs.

For a modern, high-tech NoVA home, a multi-day power outage is more than an inconvenience—it’s a crisis. It means no heat or AC, frozen pipes in the winter, no running water (if you are on a well pump), no internet, and a refrigerator full of spoiled food. The solution is clear: a Standby Generator.

5.2. Standby Generators: Sizing, Fuel, and Automatic Transfer Switches

The standby generator is the ultimate integration of electrical and mechanical expertise. It’s an engine (mechanical) that powers your home’s electrical panel (electrical). It must be installed by someone who understands both trades perfectly.

- Sizing is Everything: The biggest mistake a homeowner makes is buying an undersized generator. We use a rigorous load analysis to determine your home’s critical needs—the HVAC air handler, the furnace, the well pump, the refrigerator, and perhaps a few critical circuits. We calculate the *starting wattage* (inrush current) of all the major motors, which is often 3 to 5 times the running wattage. A failure to size correctly means the generator will stall when the AC unit kicks on.

- Fuel Source: We typically recommend Natural Gas (NG) for homes in dense service areas like Alexandria, as the supply is virtually unlimited. For homes outside the main gas service, we recommend Propane (LP), which requires a large, well-maintained tank.

- Automatic Transfer Switch (ATS): This is the magic component. The ATS is wired directly into your main electrical panel. When it senses a power failure, it tells the generator to start. Once the generator is running smoothly, the ATS safely disconnects your home from the utility line and connects it to the generator. This is a highly specialized electrical installation—done entirely by my Master Electrician team—that ensures you never accidentally backfeed power onto the utility lines, which could seriously injure a utility worker.

5.3. Portable Generators: The Right Way and the Wrong Way (Safety First!)

I understand that a whole-home standby generator is a significant investment, and many homeowners use a portable generator. As a Master Electrician, I issue this stern warning: NEVER, under any circumstances, run a portable generator by plugging it into an outlet in your home. This is called *backfeeding*, and it is a deadly practice that can electrocute a lineman working on your street.

The *only* safe, legal way to use a portable generator to power your home’s systems is through a professionally installed Manual Transfer Switch (MTS) or an Interlock Kit.

- Interlock Kit: A metal plate installed on your panel that physically prevents the main utility breaker and the generator breaker from being on at the same time.

- Manual Transfer Switch: A smaller, separate panel that only powers 6-10 critical circuits (furnace, refrigerator, lights).

I strongly recommend the latter, and I will only install these solutions to code, ensuring your family’s safety.

5.4. Interlock Kits vs. Automatic Transfer Switches: The Electrical Difference

When choosing your system, the difference between these two components defines the convenience level:

| Feature | Automatic Transfer Switch (ATS) | Manual Transfer Switch (MTS) / Interlock Kit |

|---|---|---|

| Generator Type | Whole-Home Standby Generator | Portable or Small Standby Generator |

| Operation | Fully automatic; starts generator and transfers power instantly. | Requires manual starting of the generator and flipping the switch/breaker. |

| Power Scope | Can power your entire home, including AC and furnace. | Powers only a few selected circuits (refrigerator, lights, furnace fan). |

| Installation | Complex, requires dedicated service wiring and major electrical work. | Simpler, but requires careful identification of critical circuits. |

For maximum peace of mind in NoVA’s volatile weather, the ATS with a whole-home standby is the superior solution.

5.5. The Generator Permit Process: Why You Can’t DIY This in Fairfax County

Generator installation is not a weekend project. In Fairfax County, Loudoun County, and all municipalities, the installation requires permits from both the Electrical Department (for the wiring, panel, and ATS) and the Building/Zoning Department (for the physical placement, concrete pad, and gas line).

- Zoning: Generators must be placed a specific distance from property lines, windows, and vents to comply with noise and carbon monoxide safety regulations.

- Gas/Propane Line: A licensed professional must run the dedicated gas line from your meter or tank to the unit.

- Electrical Inspection: The entire installation must pass a rigorous inspection by the county.

PRO Electric plus HVAC handles all the permitting, inspections, and utility coordination from start to finish. Our commitment is to a safe, legal, and code-compliant installation that protects your investment and your family.

5.6. Whole-Home Surge Protection: Guarding Your HVAC and Electronics

A power outage is only one side of the coin; the other is the devastating effect of a power surge.

A surge is a brief spike in voltage that can happen for several reasons: a lightning strike nearby, a utility switching on/off, or even the compressor in your AC unit cycling off. These spikes travel down your wires and are often too fast for a standard plug-in strip protector to catch.

Modern HVAC systems rely on delicate, expensive electronics: Variable Speed Drives, Control Boards, and Smart Thermostats. A single surge can fry the circuit board in your furnace, leaving you without heat, or destroy the inverter drive in your heat pump, leading to a multi-thousand-dollar replacement.

My solution is to install a Whole-Home Surge Protector (Type 2) directly onto your main electrical panel. This device intercepts surges before they can enter your home’s internal wiring, shunting the excess energy safely to the ground. For minimal cost, it provides maximum protection for your entire electrical system, including your HVAC and generator components. This is a simple, smart, and necessary upgrade for every NoVA home.

5.7. Generator Maintenance: Preventing the Failure When You Need It Most

A generator is a motor, and like any motor, it requires maintenance. When the power goes out, the generator must fire up instantly—it has no second chance.

My maintenance plan includes:

- Annual Oil and Filter Change: Simple mechanics, but crucial for longevity.

- Battery Check: Ensuring the starting battery is charged and corrosion-free.

- Transfer Switch Test: Manually running the generator and cycling the ATS to confirm it reliably transfers power.

- Critter Inspection: Keeping the engine compartment free of nests and debris (a constant problem in our wooded areas).

I often hear stories of generators that failed during the first hour of a massive snowstorm. In 90% of those cases, the failure was due to a dead battery or a maintenance neglect.

5.8. How a Generator Installation Requires Integrated HVAC Expertise

When sizing and wiring a generator, I must know exactly how your HVAC system works.

- Heat Pump: Does it have electric strip heat? If so, the generator must be sized to run *at least* the air handler and the most efficient stage of the heat pump, while we can choose to lock out the extremely power-hungry auxiliary strips.

- Furnace: We only need to wire in the dedicated circuit for the blower motor and the control board. The gas valve takes a tiny electrical load.

The PRO advantage is that I do not need to call a separate HVAC technician to ask these questions. I can look at your furnace, read the BTU rating, check the blower motor’s amp draw, and wire the entire system from the generator to the panel and the HVAC unit itself, ensuring a perfect, safe, and efficient power management plan.

5.9. Case Study: The Derecho and the 12-Day Power Loss in Loudoun

A few years back, the Derecho swept through Loudoun County, and a specific client of mine was without utility power for 12 days. They had installed a 22kW whole-home standby generator with us two years prior.

For those 12 days, their family was the only one on the street with full power. Their AC ran during the humid heat, their refrigerator stayed cold, their internet worked, and their children were able to charge their devices. They spent the outage enjoying their home instead of evacuating. That level of comfort and security is the return on investment for a properly sized, expertly installed, and meticulously maintained standby generator. It is the ultimate insurance policy against the chaos of Northern Virginia weather.

↑ Go back to Table of Contents

Chapter 6: When Things Go Wrong: My Technician’s Guide to Troubleshooting and Emergency Calls

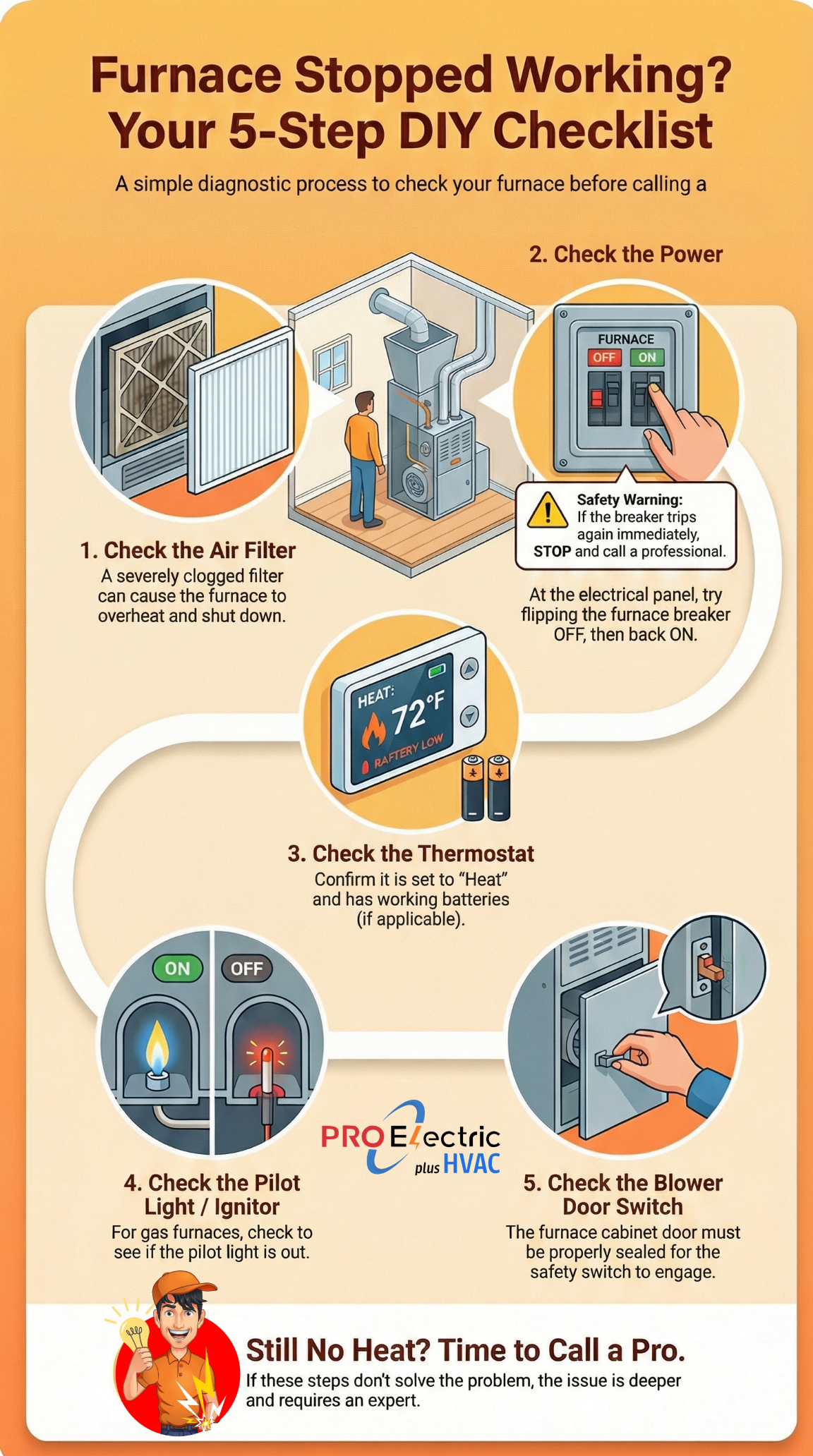

6.1. The “No Heat” Call: My Top 5 Diagnostic Steps (Filter, Power, Thermostat, Pilot, Capacitor)

When the phone rings in the dead of a January night from a homeowner in Fairfax or Prince William, the stress in their voice is palpable: “My furnace is dead! I have no heat!”

Before I or one of my HVAC certified technicians even steps foot in the door, I encourage homeowners to run through a quick list. It might save you a service call fee, and it gives us vital information.

- Check the Filter (HVAC): A severely clogged filter can suffocate the furnace, causing it to overheat and trip a safety limit switch. This is often the simplest fix.

- Check the Power (Electrical): Go to the main electrical panel. Is the dedicated breaker for the furnace/air handler tripped? If so, try flipping it *completely off* and then *back on*. If it trips immediately, STOP—you have a short circuit, and you need a PRO.

- Check the Thermostat (HVAC/Electrical): Is the fan set to “Heat?” Is the fan set to “Auto?” Are the batteries dead (for older models)? Is there a power-loss warning on the display?

- Check the Pilot/Ignitor (HVAC/Mechanical): For gas furnaces, is the pilot light out? For modern furnaces, is the Hot Surface Ignitor (HSI) glowing white-hot? If it’s not glowing, the HSI is either dead (HVAC) or not receiving power (Electrical).

- Check the Blower Compartment Switch (Electrical): Is the furnace cabinet door properly sealed? Most furnaces have a door safety switch. If the door is even slightly ajar, the switch will kill all power to the furnace.

If these five steps fail, the problem is deeper, and that is where my dual expertise really shines. We move immediately to testing the transformer, control board, and component amperage.

6.2. The Short-Cycling AC: A Symptom of Larger Electrical or Refrigerant Issues

A frequent summertime call is the AC that runs for 3 minutes, then shuts off and starts again a minute later. This is called Short-Cycling, and it is extremely hard on the compressor motor. It’s also ineffective for cooling and terrible for dehumidification.

Short-cycling is rarely a simple component failure; it is usually a *symptom* of a systemic issue:

- HVAC-Related Causes:

- Oversizing: The unit is too large for the home and cools too fast (as discussed in Chapter 2).

- Low Refrigerant: Low pressure activates a low-pressure safety switch, which trips the unit off.

- Clogged Coil: Dirty condenser or evaporator coils prevent efficient heat transfer, causing the compressor to overheat and trip a high-pressure safety switch.

- Electrical-Related Causes:

- Voltage Sag: The power going to the compressor is unstable or dipping, causing the unit’s internal electrical overload protection to trip it off.

- Failing Start/Run Capacitor: The capacitor is a battery-like electrical component that gives the compressor the massive jolt of power needed to start. If it is weak, the compressor struggles to start, trips the thermal overload, and shuts down.

I’ll test the voltage and capacitance immediately upon arrival. This pinpoints the issue in minutes—something an HVAC-only tech might miss if they only focus on refrigerant pressures.

6.3. The Sound of Trouble: Interpreting Bangs, Grinds, Hisses, and Squeals

Your HVAC system is supposed to run smoothly and quietly. Any new, loud noise is your system screaming for attention.

| The Sound | Potential Cause (HVAC/Mechanical) | Potential Cause (Electrical/Component) |

|---|---|---|

| Screaming/Squealing | A failing belt or a dying Blower Motor Bearing (common in older units). | Not typically electrical, but the motor is failing. |

| Loud, Repeated Clicking | The main Contactor in the outdoor unit is engaging/disengaging rapidly. | Contactor failure (needs replacement) or low 24V signal from thermostat (electrical wiring/thermostat issue). |

| Loud Bang/Rumble | Sudden ignition of gas after a delay (a dangerous condition known as delayed ignition). | Faulty gas valve or failing ignition system (electrical-controlled). |

| Hissing/Bubbling | Refrigerant leak (hissing from outdoor unit) or clogged condensate drain line (bubbling from drain). | Not electrical, but leads to electrical strain (low charge = harder running). |

| Grinding/Rattling | The Motor Blower Wheel is loose, or there is a physical object hitting the fan blades. | The Blower Motor is failing and the bearings are seizing up. |

My first step is always to safely kill the power at the main shutoff and then physically inspect the motor. Many mechanical failures are preceded by an electrical problem, like an aged motor drawing too much current, causing excessive heat and bearing failure.

6.4. Water Leaking from the Ceiling: The Clogged Condensate Drain Line

This is an extremely common service call in the muggy summers of NoVA. When your AC or heat pump is cooling, it is dehumidifying—pulling moisture out of the air. This moisture is collected in a condensate pan and drained out through a condensate line (usually a small PVC pipe).

If this drain line gets clogged with algae, sludge, or dust (a common issue in the crawlspaces of older homes), the water backs up. The pan overflows, and the water starts dripping onto your ceiling, often near the air handler in the attic or utility closet.

Modern air handlers have a Condensate Safety Float Switch installed in the drain pan. When the water level gets too high, this electrical switch trips, shutting off the entire unit to prevent damage. When your AC won’t run, and you see water, the solution is often a simple cleaning of the drain line, followed by a check of the float switch wiring to ensure it’s functioning correctly.

6.5. The Electrical Panel That Hums: The Warning Sign of a Loose Connection

Back to the electrical panel (Chapter 3). If you hear a loud, consistent humming or buzzing, it is a definitive warning sign of a problem usually a loose connection at a terminal or a failing breaker.

A loose connection creates heat, and the humming sound is the electricity vibrating as it fights to bridge the gap. Ignoring this sound is like ignoring smoke—it will eventually lead to a fire.

When I get a call about a humming panel, it is always treated as an emergency. I immediately shut off the main power and systematically check and re-torque (tighten) every single connection point—the main lugs, the neutral bar, the ground bar, and the screw terminals on every breaker. A simple tightening can prevent a major, life-threatening disaster.

6.6. Why I Carry an Ammeter: Diagnosing Failing Motors and Compressors

I do not guess. I diagnose with facts. My most important tool is my True RMS Clamp Meter (Ammeter).

I use this to clamp around the wires powering any motor—the AC compressor, the furnace blower, the well pump. The ammeter tells me exactly how many amps (current) the motor is drawing.

- If the motor’s rated amperage is 12.0 amps, and my meter reads 18.0 amps, the motor is failing. It is working too hard due to seized bearings or a mechanical issue, and it will soon burn out and trip the breaker for good.

- If the motor is rated for 12.0 amps, and my meter reads 6.0 amps, the motor is starving for power (often due to low voltage) or being fed an incorrect signal from the control board.

By testing the electrical draw, I can accurately predict a mechanical failure long before it happens, allowing us to perform a preventative repair and save the homeowner from an emergency breakdown.

6.7. Frozen Coils: It’s Not Just Low Refrigerant (It’s Often Airflow)

When you look into your indoor air handler and see the evaporator coil covered in a thick layer of ice, you immediately think, “It’s low on refrigerant!” While a leak is a frequent cause, the most common cause is actually restricted airflow.

Remember: the coil needs warm air from your house to absorb the heat and stay above freezing.

- The Number One Culprit: A severely clogged air filter.

- Other Causes: A failing blower motor (not moving enough air) or a major duct leak/restriction.

In all cases, the solution is the same: the system needs to be shut off to thaw completely, the airflow restriction must be removed (new filter, motor repair), and then the system can be safely restarted. My first step is always to check the filter and the blower motor’s amperage draw before I put my gauges on the refrigerant line.

6.8. When Your Thermostat Display is Blank: The Fuse or the Transformer?

A blank thermostat screen is a common service call that demonstrates the electrical-HVAC connection perfectly. The problem is always a loss of low-voltage (24V) power.

- The Fuse (Electrical/Safety): The main control board in the air handler has a small, inexpensive 3-amp fuse (often a car fuse) that protects the expensive board. If a low-voltage wire is accidentally shorted (perhaps by a homeowner messing with the thermostat or a wire being pinched), this fuse blows to save the board.

- The Transformer (Electrical/Component): This is the component in the air handler that steps down the high-voltage house power (120V) to the low-voltage control power (24V) for the thermostat, control board, and relays. If the transformer fails, no 24V power is produced.

I check the fuse first. If the fuse is blown, I replace it and see if it holds. If it blows again, I know there is a short in the low-voltage wiring. If the fuse is good, I test the transformer. If the transformer is not outputting 24V, it is the culprit. A proper dual-trade professional will carry both fuses and the specific transformer needed to fix this issue immediately.

6.9. The Danger of DIY Electrical Repairs: Why I Get Called In After the Fact

I understand the desire to save money, but please, do not try to do your own major electrical or HVAC work. I am often called in to fix the mistakes of well-meaning homeowners or unqualified handymen, and those repairs are always more expensive than the original job would have been.

- Wrong Wire Gauge: Using a wire too thin for the amperage load leads to overheating and fire.

- Loose Connections: I’ve already detailed the fire hazard of this (Section 6.5).

- Improper Breaker Type: Installing a standard breaker where an AFCI or GFCI is required.

In the highly regulated world of NoVA contracting, safety and code compliance are paramount. A licensed Master Electrician and HVAC-certified professional knows the specific requirements for every component and wire. Your family’s safety is worth the service fee.

6.10. What to Do Before I Arrive: A Checklist for a Faster Service Call

If you have a problem, you want it fixed *now*. Help me help you by having this ready when my team arrives:

- Clear the Path: Ensure the area around your furnace, air handler, and outdoor unit (condenser) is clear and easily accessible.

- Access the Panel: Know exactly where your main electrical panel is and ensure it’s unlocked/accessible.

- Note the Error Code: If your furnace or AC has a small LED light on the control board, note the blinking pattern or the error code on the thermostat.

- Know the History: Be ready to tell me when the unit was last serviced, what the issue was, and what was done.

- Check Simple Things: Please, check the thermostat setting and the circuit breaker one last time.

Your preparation saves us diagnostic time, and a faster diagnosis means a faster, more cost-effective solution for your home.

↑ Go back to Table of Contents

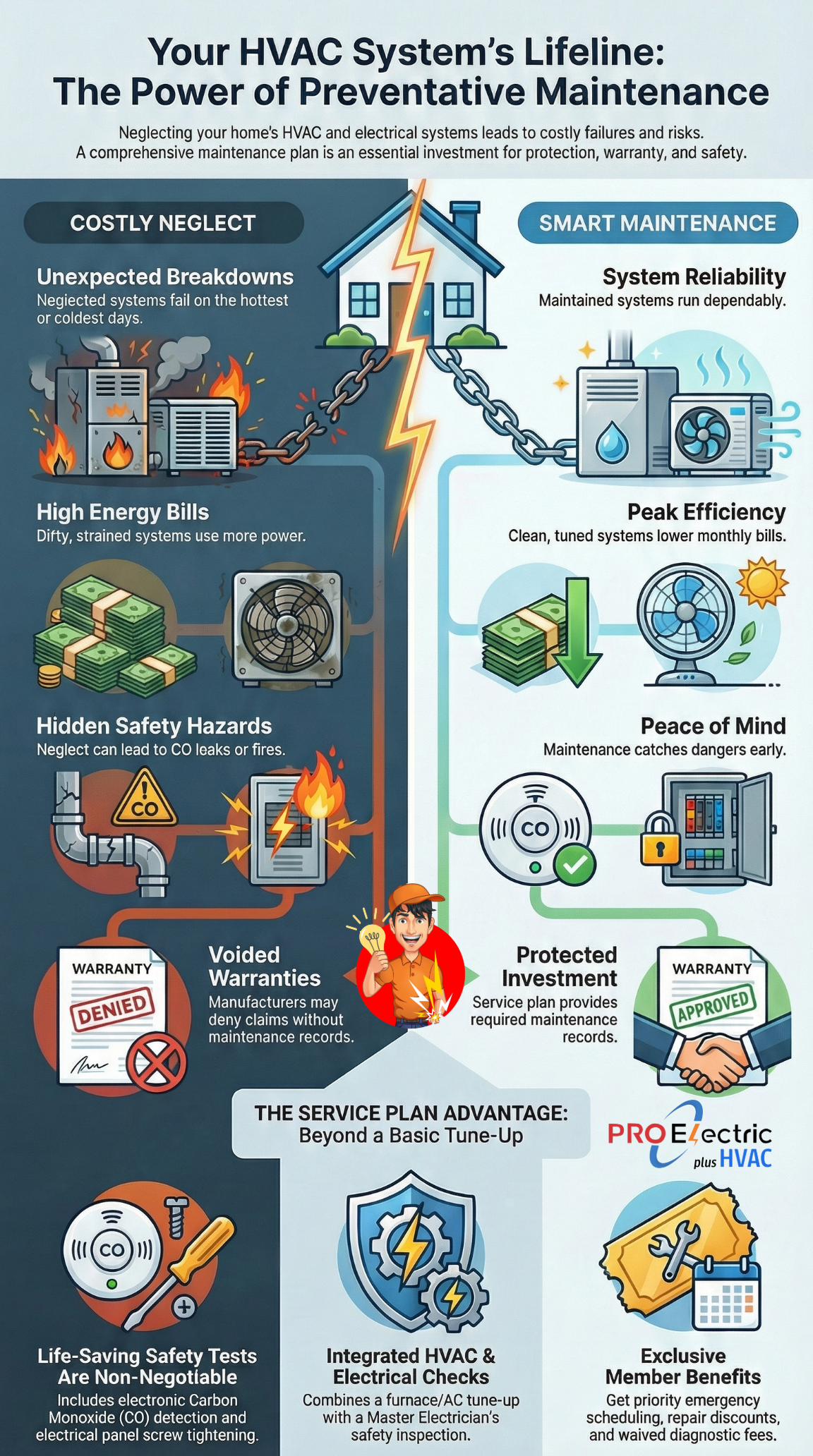

Chapter 7: The Unsung Hero: Detailed Preventative Maintenance and System Lifeline

7.1. The True Cost of Neglect: Why Maintenance Pays for Itself (and Then Some)

I often tell my clients in Arlington and Fairfax: “You wouldn’t drive your car 100,000 miles without an oil change, so why would you run your furnace for 10,000 hours without a tune-up?”

Preventative maintenance is the single most undervalued service in the HVAC and Electrical industries. Homeowners see it as an expense, but I see it as a mandatory investment that provides four critical returns:

- Safety: Catching gas leaks, frayed wires, or failing safety controls before they become dangerous.

- Efficiency: Keeping coils clean and motors running smoothly dramatically lowers your monthly Dominion or Washington Gas bill.

- Longevity: Reducing wear and tear extends the life of your expensive compressor and furnace motor.

- Warranty Protection: Most manufacturer warranties are voided if the system has not been professionally maintained annually.

In the high-stress, stop-and-go climate of Northern Virginia, neglect means the system runs harder, costs more to operate, and will inevitably fail on the coldest or hottest day of the year.

7.2. The Comprehensive HVAC Tune-Up Checklist

My PRO team performs a rigorous, multi-point inspection that is far more detailed than the typical “clean the coil and leave” service you might get elsewhere. Our seasonal tune-ups are mandatory, not optional, for anyone serious about system performance.

Spring/AC Tune-Up Checklist (Critical for Summer):

- Refrigerant Charge Check: Using gauges, verify the correct superheat and subcooling (the scientific measure of the refrigerant). A low charge means a leak we must find.

- Condenser Coil Cleaning: Power-washing the outdoor coil to remove the grime, pollen, and debris that chokes efficiency (especially critical in our heavily wooded suburbs).

- Condensate Drain Clear: Using a wet-vac or pressurized air to flush the drain line, preventing clogs and basement flooding.

- Check Electrical Connections: Tightening all high and low-voltage connections on the outdoor unit, contactor, and control board (a safety and efficiency check).

- Test Contactor and Capacitors: Checking the Amperage Draw of the motor and compressor and replacing weak, failing capacitors before they burn out the compressor.

- Thermostat Calibration: Ensuring the thermostat reading is accurate and the cycle times are appropriate.

Fall/Furnace Tune-Up Checklist (Critical for Winter):

- Carbon Monoxide (CO) Safety Test: The absolute most critical step. We test the air around the furnace for CO leaks and inspect the Heat Exchanger for cracks that could be leaking this odorless, lethal gas into your home.

- Gas Pressure Check: Calibrating the gas valve to ensure the furnace receives and combusts the proper amount of fuel.

- Ignition System Test: Checking the flame sensor and the Hot Surface Ignitor (HSI) to ensure safe, instant ignition.

- Blower Motor Amperage: Testing the motor’s power draw to catch an impending failure (the motor is often the highest electrical load).

- Flue/Vent Inspection: Ensuring the exhaust vent is clear of blockages (nests, debris) and that the combustion air is being drawn in properly.

7.3. The Electrical Service Check: Integrating Safety into the Maintenance Schedule

This is the component that makes PRO Electric plus HVAC unique. While the HVAC technician is cleaning the coil, the Master Electrician side of the team is performing an integrated safety check that most companies completely miss.

The PRO Electrical Safety Check:

- Panel Lug Retorque: As detailed in Chapter 3, physically tightening the screws on the main lugs and major breakers (AC, Furnace, Water Heater) to prevent arcing and fire.

- Voltage and Amperage Test: Verifying that the voltage coming into the panel is stable (no brown-out) and that the main service wires are not overheating under load.

- GFCI/AFCI Breaker Test: Manually tripping these safety breakers to ensure they function instantly.

- Surge Protection Inspection: Checking the status lights on your whole-home surge protector to ensure it is still active and hasn’t been compromised by a previous spike.

- Dedicated Circuit Integrity: Tracing the dedicated circuit from the panel to the HVAC unit to look for any signs of wear, fraying, or accidental damage.

This dual-system check provides a level of safety and reliability that a single-trade service simply cannot offer.

7.4. Carbon Monoxide (CO) Safety: Why This Check Is Non-Negotiable for Gas Appliances

I treat the Carbon Monoxide check with the utmost seriousness. CO is the silent killer, and its source in a NoVA home is almost always a faulty gas furnace, water heater, or boiler.

During the Fall Tune-up, we use calibrated electronic sniffers to test for CO around the furnace and near the vents. The major danger is a crack in the Heat Exchanger—the metal chamber that separates the combustion gases (containing CO) from the air being circulated into your home. A cracked heat exchanger can leak CO into your living space.

If my technician detects CO, the unit is immediately red-tagged (shut down), and the homeowner is advised to evacuate and ventilate. We will then work with you to secure a safe replacement system. This is a life-and-death safety check that cannot be compromised.

7.5. Extending the Life of Your Water Heater (Both Electrical and Gas)

Your water heater—whether electric, gas, or a heat pump model—is a major appliance that often lives in the same mechanical space as your HVAC unit and deserves the same maintenance attention.

- Gas Water Heater: We check the flue/vent for blockages and inspect the T&P (Temperature and Pressure) relief valve. We also check the condition of the pilot or ignitor.

- Electric Water Heater: We test the upper and lower electrical heating elements and thermostats, check the wiring for signs of scorching, and ensure the dedicated breaker is functioning.

- Tank Cleaning: For both types, if applicable, we recommend and perform a tank flush to remove sediment and scale, which dramatically improves efficiency and extends the life of the tank.

Since the water heater is often on a large dedicated circuit, its electrical health is part of my Master Electrician assessment of your home’s overall electrical fitness.

7.6. Priority Scheduling: The Underrated Benefit of a Service Agreement

Here is the most practical benefit of joining a PRO Electric plus HVAC service plan: Priority Scheduling.

When the temperature hits 98°F in August, or the wind chill is 5°F in February, every HVAC company in the region is slammed with emergency calls. If you are not a plan member, you will be placed in the queue behind dozens of other non-members. Your wait time could be days.

As a PRO Service Plan member, you are moved to the front of the line. Your emergency call is routed as a priority, ensuring my team gets to your home in Loudoun, Arlington, or Prince William quickly, minimizing your family’s exposure to the extreme NoVA weather. That guaranteed, fast response time is the peace of mind you are truly buying.

7.7. Documentation and Warranty Protection: Proof of Maintenance for Claims

If your expensive compressor or furnace control board fails under warranty, the manufacturer will almost always demand proof of annual professional maintenance. If you cannot provide documentation that a licensed, certified technician has performed the required service, the manufacturer has every right to void your warranty.

Our service plan provides you with detailed, written reports after every tune-up, complete with photos, readings, and a clear list of what was checked and what was found. This professional documentation is your insurance against an expensive warranty denial. We track this data for you, ensuring your records are always audit-ready.

7.8. Exclusive Benefits of a Service Agreement

Our service agreement is designed to make system ownership affordable and predictable:

- Discounted Repairs: Plan members receive a significant discount (often 10-15%) on all parts and labor for any necessary repair.

- No Diagnostic Fees: If you have an issue outside of the regular tune-up, the service call fee is waived.

- Reduced Installation Costs: Preferred pricing on new central installations (AC, Furnace, Battery-powered Backup Generator).

- Guaranteed Response Time: The priority scheduling we discussed.

In essence, you are enrolling your home in a maintenance program run by a certified Master Electrician and HVAC expert, which dramatically lowers your risk of emergency failure and cuts the cost of unexpected repairs.

7.7. Final Thought on Preventative Maintenance

Your HVAC and Electrical systems are the most expensive and critical components of your home. You spent a significant amount of money to install them. Spending a small, predictable amount annually on proper care that integrates both the electrical and mechanical sides is good stewardship. Don’t wait for the breakdown; enroll in the PRO maintenance plan today.

↑ Go back to Table of Contents

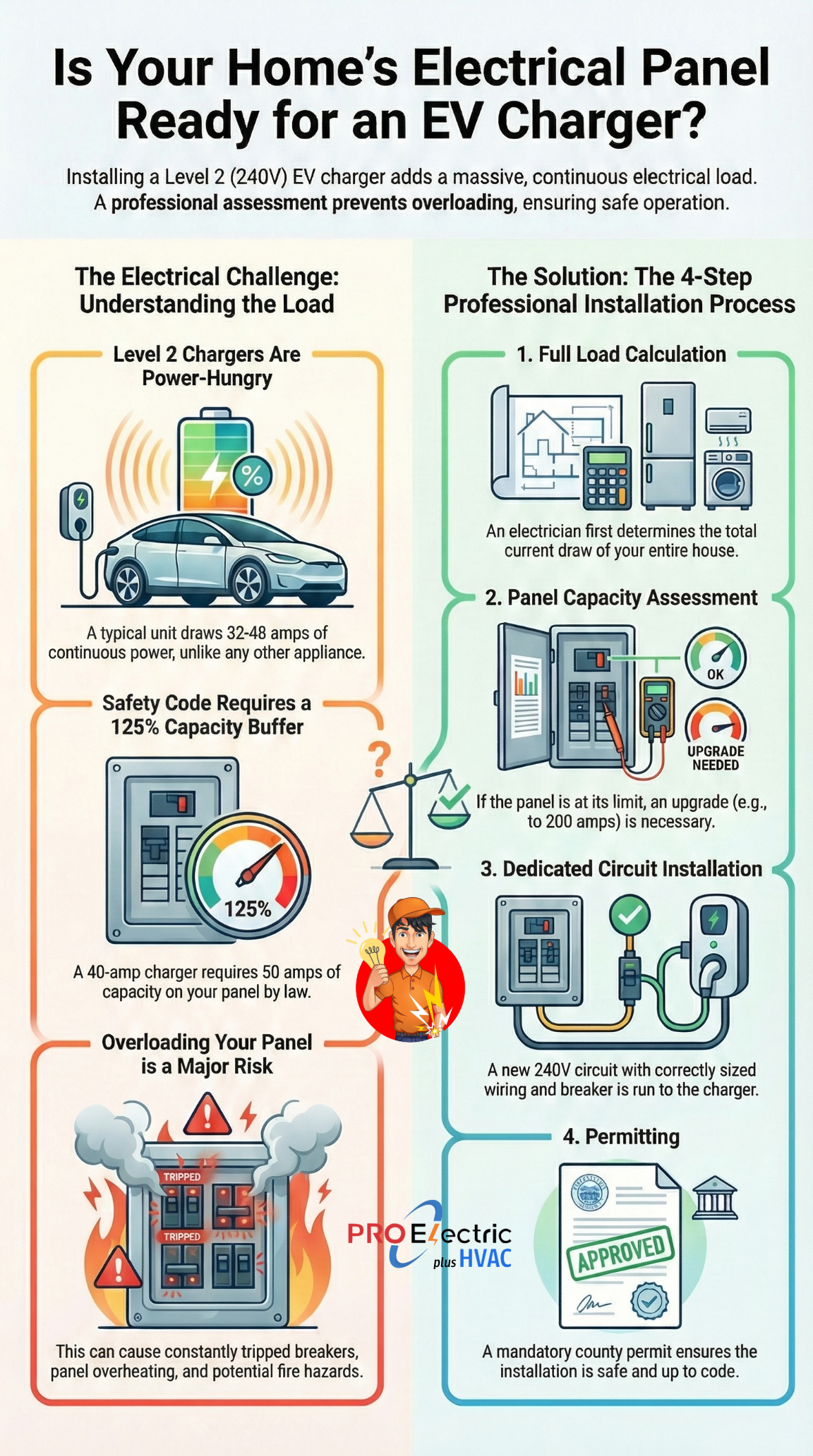

Chapter 8: The Electrified Home: EV Charging and High-Efficiency Upgrades

8.1. The EV Revolution is Here: Why Your Home Needs a Level 2 Charger

The future of transportation is electric, and Northern Virginia is on the cutting edge of this revolution. I’ve seen the demand for Electric Vehicle (EV) chargers skyrocket in the last few years, particularly among my clients in the denser, professional communities of Arlington and Fairfax.

The challenge for the homeowner is not just buying a charging unit; it’s making sure the home’s electrical infrastructure can safely and reliably handle the massive, sustained load of a Level 2 (240V) Charger.

- Level 1 (120V): Plugs into a standard wall outlet. It’s slow—it only adds about 3 to 5 miles of range per hour. It’s fine for a trickle charge, but it’s not practical for daily driving in NoVA.

- Level 2 (240V): This is the gold standard, adding 20 to 60 miles of range per hour. It is a powerful, high-amperage, dedicated circuit that fundamentally changes your home’s electrical load profile.

When I install a Level 2 charger, I integrate your car’s needs into your home’s overall electrical health, ensuring it won’t jeopardize the operation of your AC or furnace.

8.2. EV Charger Installation: A Detailed Look at Panel Capacity and Load Calculation

This is the quintessential dual-trade problem: the EV charger is a large electrical load that must be managed correctly.

A typical Level 2 charger draws 32 to 48 amps of continuous current. When calculating the panel load (Chapter 3), the National Electrical Code requires us to use 125% of that continuous load. For a 40-amp charger, we must account for 50 amps of capacity.

If your electrical panel is already at or near its limit (as is the case for most older 100-amp homes), installing a 50-amp breaker without upgrading is a recipe for disaster. The main breaker will constantly trip, or worse, the panel will overheat.